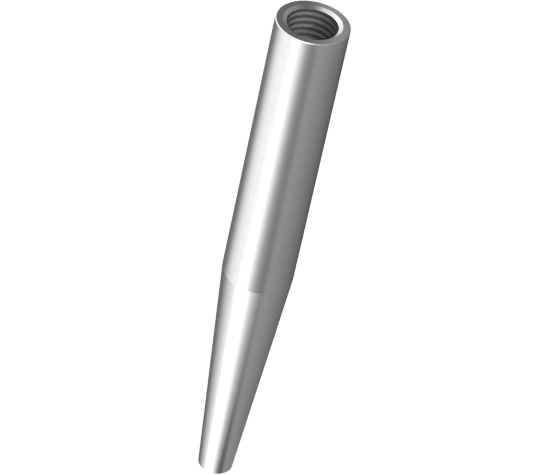

These Thermowells are turned & drilled from solid bar stock. This enables them to be placed within processes which experience or operate under high pressure. They consist of a stainless steel shaft which can be straight or tapered. There is a weld collar to facilitate the thermowell to be welded in to the process & an internal instrument connection thread. The bore is drilled out to 0.3mm larger than the intended sensor to be assembled giving a snug fit to encourage good thermal conductivity.

Performance Characteristics

Shank Style

- Straight

- Tapered

Shank Diameter

- Configurable

Insertion Length

- 20 … 450 mm

Process Connection

- Weld Socket

- Weld in

Instrument Thread

- ½”BSP

- ½”NPT

Internal Diameter

- 6.35

- 6.7

Thermowell Material

- AISI 316L (1.4404)

- Hastelloy C

- Duplex 2205

- Super Duplex S32750

Surface Roughness Wetted Parts

- Ra ≤ 0.8 µm

Performance Characteristics

- Max. Temperature & Pressure

- Depending on:

- Thermowell design

- Dimensions

- Material

- Coating

- Flange pressure rating

- Process conditions

- Flow rate

- Density of medium

Certification Options

- 3.1b Material Cert

- Surface Finish Cert

- Wake Frequency Cert